Lens grinding

Microbas delivers double-sided ground lens substrates with high precision and “ready to polish” high finish surfaces. Microbas’ proven lens grinding process delivers optical axis alignment within microns while also ensuring excellent wedge precision. The strengths of our process include:

- Capabilities of a wide range of geometries

- Machining strategies to minimise subsurface damage down to 20 microns

- Minimal form error

We work in most optical glass types including Fused Silica, Borosilicate glass etc from world-leading glass manufacturers.

Mirror grinding

- Spherical mirrors

- Aspherical mirrors

- On- and off-axis mirrors

- Freeform mirrors

We provide ready to polish ground surfaces with:

- Capabilities of a wide range of geometries

- Down to 20µm sub surface damage

- Minimal form error

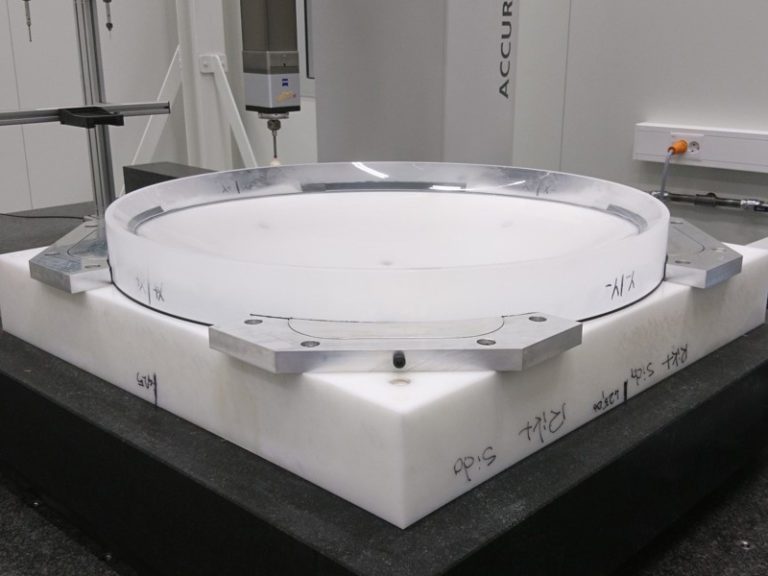

Mirror Lightweighting

Microbas has capabilities and long experience in mirror lightweighting in optical glass and glass ceramics. We often collaborated with our customers in the early phase of the design to optimize for a robust process whilst still maintaining correct centre of gravity, lowest possible weight and sufficient mechanical strength.

SemiConductors & Displays

Optics and space

Machine building

Manufacturing

Contact us

Please contact us for enquiries or orders. Send a sketch of your prospective product and we will get back to you shortly with a quotation.